®®CASE STUDY: RHINO CARBON FIBER® CRACK REPAIR

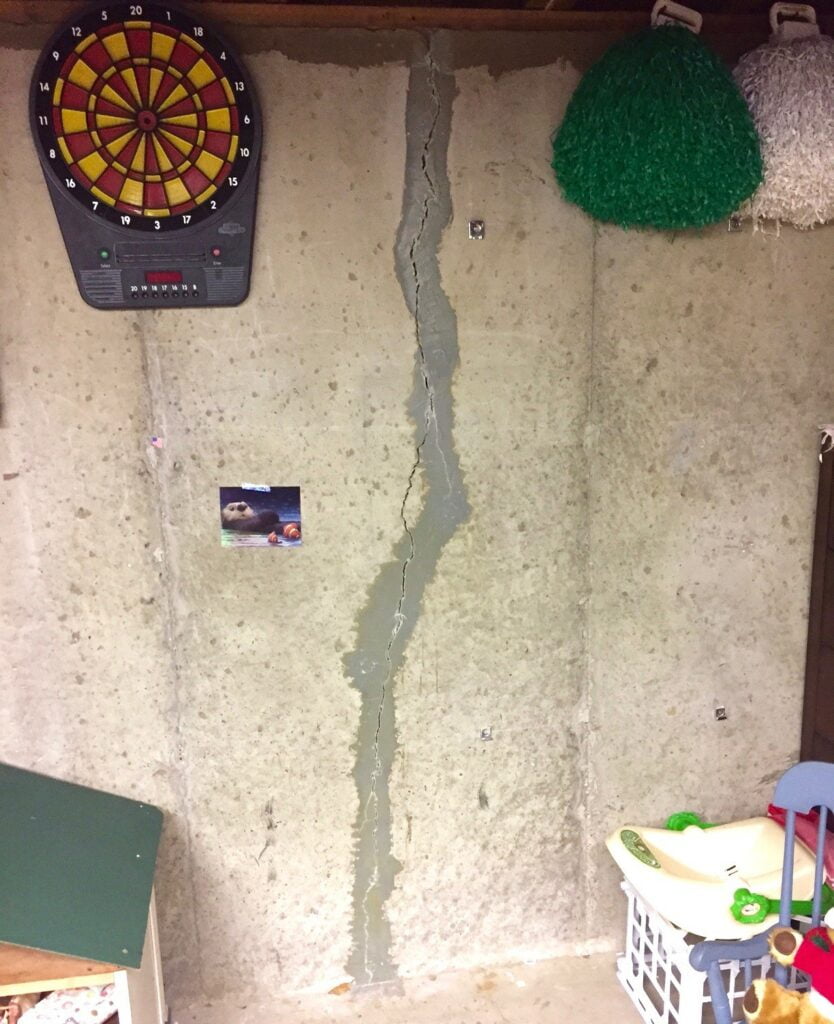

Recently, a homeowner in Overland Park asked SEALED to inspect a previously repaired crack in his basement. Our first observation was that this crack had been covered or capped with epoxy, but had never been injected or sealed. Epoxy is a very good adhesive, but has no flexibility. So when additional settling occurred, the epoxy simply cracked as you can see in these pictures:

The first order of business was to remove the dried and cracked epoxy to get back to a clean concrete surface.

The crack was wider than 1/4” so our recommendation was to fill the crack as deep as possible with hydraulic concrete and then cover and seal it with a Rhino Carbon Fiber® mesh strap The next picture shows the concrete in the crack after the old epoxy was removed:

You will notice that there are ports and epoxy at the very bottom of the crack. This portion was narrow enough to inject but too narrow to get any concrete into it. We ended up using almost a full cartridge of expanding polyurethane in just these four ports so there was plenty of space inside the wall and some of our material went up behind the concrete.

After the concrete had cured we removed the ports at the bottom of the crack and applied a different kind of epoxy over the crack. We then placed the Rhino Carbon Fiber® strap in tension over the crack. Lastly, we reapplied epoxy so that the carbon fiber is now embedded between two layers of epoxy. This crack won’t leak and the wall won’t move, which means a happy homeowner.